POWERPOINT PRESENTATION

ELECTRICAL ENGINEERING

This blog contain some PPT on protective devices. This PPT helps you in activity classes, viva and seminars. Now a day this mandatory in every college/university for student take participate in activity classes to present them self through PPT, and build up confidence.

"About this PPT, it contain editable/full excess with many effects and attractive slides".

Download link is down.

INTRODUCTION

In the power system, whenever any

abnormal condition occurs, protective devices are employed to isolate the

abnormal condition instantaneously or in some cases, after the predetermined

time delay. The faulty section of the power system

must be isolated from the healthy section automatically before it could

diameter costly equipment or apparatus. The most common protective devices

employed in the power system to protect the system against heavy currents are

fuses and relays. Moreover the protection is also provided for the persons

operating the power system which achieved by earthing all the metallic bodies

of all equipment and apparatus.

Sample slide:-

Main features of a good

protective devices

A good protective gear must

have following main features:

a)Selectivity: The

ability of protective gear to select correctly the faulty section of the power

system and disconnect the same without disturbing the rest of the system is

called selectivity is called selectivity.

b)Sensitivity: The ability of the protective gear to

operate with low value of actuating quantity is called its sensitivity.

c)Reliability: The ability of protecting gear to

operate under predetermined condition without fail is called

its reliability.

d)Quickness or speed: How fast the protective gear

respond to the foult, this ability of protective gear is called its speed or quickness. The

quickness of a protective gear improve quality of service, increase safety of

life and equipment and stability of operations.

e)Economy: While selecting a protective gear,

a due consideration is given to its cost. However, when out most important

apparatus like alternator and transformer is to be protected, the economic

consideration are often subordinated to reliability.

sample slide:-

Single click download: Click here for free and safe download

Please follow me... I will upload this kind of stuff everyday.Just save the home page or mark as star.

Thank you

Type of protective

devices

1.FUSE

2.Types of Fuse

3.Relay

4.Types of Relays

5.Earthing

FUSE a fuse is a short piece of a metal

inserted in series with the circuit which melts when excessive current flows through it and does breaks the circuit.

The material used for fuse element should possess the

following properties:

•Low melting point

•High conductivity

•Free from oxidation

The common material used for Fuse

element are copper, tin-lead alloy (tin 63% lead 37%), silver, aluminum, etc. A fuse is connected in series with

the circuit to protected and carries the load current without overheating under

normal conditions. However when abnormal condition occurs an excessive current flow through it(more or

equal to predetermined value for which the future design). This raises the

temperature which metal the fuse/melt element and open the circuit. This

protects the machine or apparatus from damage which can be caused by the excessive currents.

Single click download: Click here for free and safe download

TYPES

OF FUSES

There are two main

types of fuses:

1.Low voltage fuses

, 2. High voltage fuses

1. Low

Voltage fuse:

(a)Semi-closed rewire able fuse and (b)High rupturing capacity

cartridge fuse.

2. High Voltage fuse: Two types of high voltage fuse namely

(a)Cartridge type

(b) Liquid type.

Low Voltage fuse: The essential parts of typical HRC cartridge fuse, it consists of heat

resistant ceramic cylindrical body having low coefficient of thermal expansion

and has the ability to withstand internal pressure. The body has the brass end

caps to which is welded with silver current carrying element. The space within

the body surrounding the element is completely packed with a felling powder

usually quartz, which is excellent arc

extinguishing property however chalk, plaster of paris or marble dust may also be used as

filler powder. Under normal conditions, fuse element carries the normal full

load current without overheating when a fault occur the current increases and

the fuse element melts before the fault current reaches its for peak. The heat

produced in process vaporises the melted silver element, a chemical reaction take place between the

Silver vapor and the filler powder which forms high resistive substance, which helps

in quenching the arc. these fuse may be built with a breaking capacity of 16500

to 30000 amperes at 440 voltage.

High Voltage fuse: It is essentially consists of a

glass tube filled with carbon tetrachloride solution and sealed at both ends

with brass caps. Inside the tube at one end high resistance fuse wire is welded

and the other end of the tube fuse wire is weld by strong Phosphorus bronze

spiral spring fixed to the other end of the glass tube. Sometimes a flexible

copper wire is also connected in parallel with resistance fuse element. Under

normal condition, it carries the full load current without overheating. The

corona effect is eliminated by carbon tetrachloride filled in the tube. When

fault occur the heavy current flow which melt a high resistance fuse element

and spring pull back the flexible copper wire. The arc the produce is

extinguished by carbon Tetrachloride vapour.

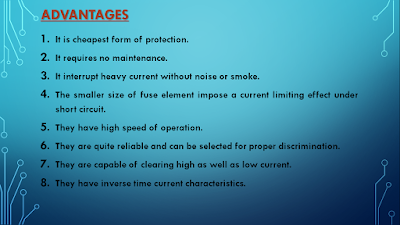

ADVANTAGES

1.It is cheapest form of protection.

2.It requires no maintenance.

3.It interrupt heavy current without noise or smoke.

4.The smaller size of fuse element impose

a current limiting effect under short circuit.

5.They have high speed of operation.

6.They are quite reliable and can be

selected for proper discrimination.

7.They are capable of clearing high as

well as low current.

8.They have inverse time current

characteristics.

DISADVANTAGES

1.Considerable time is lost in rewiring or replacing fuse after every

operation.

2.One short-circuits, determination

between fuses in series can only be obtained if there is considerable

difference in relative sizes of the fuse concerned.

3.They have to be replaced after each operation.

4.Interlocking between fuses is not possible.

5.The lack relays in complete

discrimination.

Single click download: Click here for free and safe download

RELAY a

relay is a device that detects the fault mostly in high voltage circuit and

initiated the operation of circuit breaker to isolate the defective section

from the rest of the circuit.

Fundamental requirements of a relay

The main function of protective relay

is to disconnect the faulty section of the power system through circuit breaker

abruptly before damaging The costly equipment. In order to perform this

function satisfactory, it should have the following important features:

1.Selectivity

2.2. Sensitivity

3.3. Reliability

4.4. Quickness

5.5. Simplicity

6.6. Economy

TYPES

OF RELAY

According to construction and

principle of operation

1.Thermal relay 2.Electromagnetic attraction relay 3.Induction relay

According to application

1. Overcurrent, overvoltage or over power relay 2. Under current, under

voltage or under power relay 3. Directional or reverse current relay

4.Directional or reverse power relay 5. Distance relay 6. Differential relay

According to the time of

operation:

1. Instantaneous relay 2. Definite time lag relay 3. Inverse time lag relay

4. Inverse definite minimum time

lag relay(IDMT)

THERMAL RELAY

The systematic diagram of an

indirect heated thermal relay is shown. It has bimetallic strip which is heated

by heating element. The heating element get supply from the current

transformer, an insulated contact arm caring moving contact is pivoted by and

is held by a spring. The other contact of trip circuit is fix contact. The

spring tension can be varied by changing the position of contact arm with the help of sector

plate. under normal condition the current flowing through heating element is

proportional to normal full load current of the circuit. The heat produced by

the heating element under this condition is not sufficient to band the

bimetallic strip, however when the fault occur current flow through the heating

element increased which produce heat and sufficient to band the bimetallic

strip. This release the contact arm because of spring tension the relay contact

are closed, which closes the strip coil circuit. once the trip coil circuit is

closed, it operated the circuit breaker which open the circuit. These over

currents trip relays are used mostly for motor control and their heating

element is designed to with stand short time over load upto 7 times the normal full load.

ELECTROMAGNETIC

ATTRACTION RELAY

Under normal condition the current

flowing through the relay coil at such that spring tension is more than the

attractive force of the electromagnetic relay. Therefore armature is held in

open position, however when the fault occur current flowing through the relay

coil this increased the attractive force

of electromagnet at the instant. When force of electromagnet is greater than

force of attraction. The armature still downward and moving contact bridge

become the fixed contact this close the trip coil circuit and open the circuit

breaker. The current setting can we adjust by the changing the number of

tipping. The time setting can be adjust by changing the tension of the string.

INDUCTION

RELAY

Induction type overcurrent relay

it consists of metallic disc which is free to rotate placed in between the two

Electromagnet. The upper magnet has three limbs where as the lower magnet has

two limbs. The tapped primary winding is wound on the central limb of upper

magnet which is connected to C.T of the line to be protected. The tapping is connected a plug setting bridge

by which the number of active turns of a primary winding can be varied, there

by the desired current setting is obtain. The secondary is closed winding and

wound on the central limb of the upper magnet and the lower magnet. this

winding is energized by the primary winding.. The controlling torque is

provided by connecting spiral spring on the spindle of a disc. The spindle of

the disc also carries a moving contact when the disc rotates through a preset

angle the moving contact bridges the two fix contact of the trip coil circuit.

The preset angle can be adjusted to any value between 0 to 360 degree. By

adjusting the angle the travel of moving contact can be adjusted and the relay

can be set for any desired time setting. When primary winding carry current

voltage is induced in the secondary winding by induction. Since secondary is

closed a current flow through it. The flux are produced by the current flowing

through these winding. This flux are separated by phace and space and this produce driven

torque on the disc.this torque oppose by restrain torque

provided by the spring. Under normal condition restrianing torque is more than the Driven

torque. Therefore the disc remain stationary. When the fault occur current flow

through the primary exceed the preset value. Drive the torque become more than

the stationary torque ,consquently the disc rotates and moving

contact bridges the fixed contact when the disk rotated through a preset angle.

QUESTIONS

1.Name any three

main feature of a good “Protective device”?

2.Name any two

type of protecting device?

3.What are the

advantages and disadvantages of fuse?

4. Type of relay?

5.What is relay?

6.What is fuse?

7.You can add by your self……..